Do you think that sustainable disinfection is unmanageable and impossible to implement in your company?

Choosing a sustainable alternative to traditional disinfection with chemicals and water must be simple and clear. We have developed a sustainable alternative – UVC solutions. To ensure optimal solutions for you, we create solutions for your needs. We create solutions to minimize the waste of resources and to make it simple for you to implement a UVC solution for disinfection in your production.

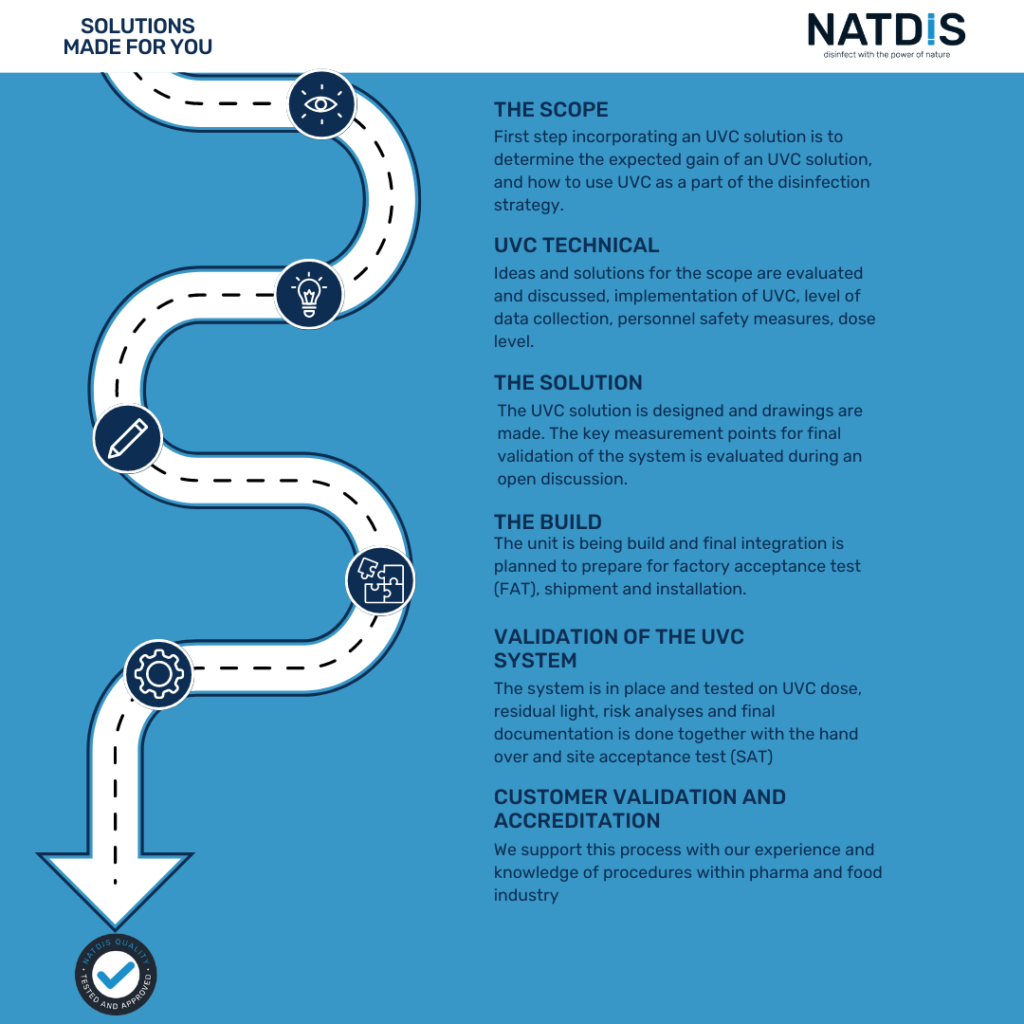

To make it easy to understand how your UVC solution is created, we have designed a process path which explains the process from problem to working solution.

Every solution starts with a need or a problem that requires a solution. You contact us to find out how we can solve your problem.

The first step in incorporating a UVC solution in your Setup is to clarify what you achieve from using UVC as disinfection, and how UVC should be used as part of the disinfection. In this process, we examine which ideas and possible solutions that will be able to solve your needs.

The second step is to examine the technical aspects of the ideas and solutions that were found in the first step. The technical regulations are incorporated into the ideas and solutions, and what is possible is examined. In this step, the UVC dose and the level of safety and data collection are determined.

In the third step the UVC solution is developed and designed. The solution is drawn and evaluated to ensure that all physical measurements and dose are dimensioned correctly.

In the fourth step, the UVC solution is built. When the UVC solution is built it is FAT tested and the implementation is planned. When the solution is approved in the FAT test it is ready to be transported and installed in your setup.

The fifth step is integrating the system into your production. UVC dose and residual light on the solution are tested. The risk analysis, the completed documentation is handed over to you, together with the takeover and the SAT test. Fifth step ensures that the solution works optimally and complies with the requirements that were defined at the start of the process.

The sixth and final step is your validation and accreditation of the solution. We guide and advise you before, during and after the implementation of your solution.

Together we develop a sustainable UVC solution for your needs. We want to solve your problem in the most optimal way with minimum waste of resources.

A UVC solution can optimize your hygiene and disinfection. We create solutions together. Contact us on +45 22 680 680 or mail@natdis.dk if we together need to find a solution for you and your company.