Get custom-made disinfection with a UVC tunnel, where we can ensure 360° automatic disinfection of your products, such as raw materials, packaging materials, boxes, cans, bags and much more.

- Contactless disinfection – Treatment with light

- Chemical-free disinfection – UVC is light

- Autonomous disinfection – Same disinfection every time

- No waiting time – works when on, off when off

- No residues – UVC of 254nm has no risk of residues

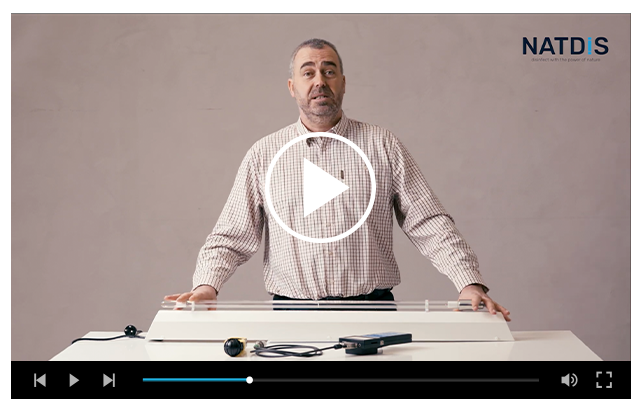

Together with Nikodan, we have developed a series of 3 specialised tunnels; check out their review on YouTube.

Nikodan has many years of experience in producing high quality process equipment for many different types of manufacturers in food, non-food and pharmaceutical industries. Read more about their competencies on their website www.nikodan.eu

What degree of disinfection should you choose?

When dimensioning a disinfection solution, you must decide which viruses or bacteria you want to get rid of. Maybe it is Corona, MRSA, Salmonella or something completely different. When we know the bacteria, virus or fungal type, we can assess whether it will make sense to go with a 90 – 99 – 99.9 or 99.99% solution. Recommendations for the degree of disinfection are based on scientific research in validated studies and compared with knowledge from the wide range of validations in which we have been involved. It could be one of those shown below or a completely different one.

Choose the right model for your needs

We have designed 3 models, which cover numerous needs of many different companies. They are all adapted to the exact task and are supplied to the transport industry, food productions and pharmaceutical production.

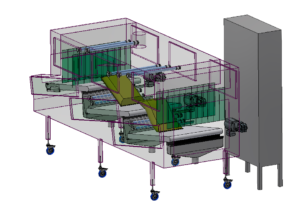

Waterfall model

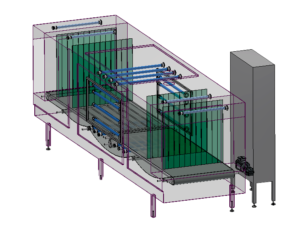

This unit is designed with three sections of conveyor belts, which move the item over stainless steel slides with UVC lamps mounted underneath. This ensures optimal treatment of all sides of the item, regardless of the type of product to be treated.

We recommend the waterfall model when there are many different types of items to be treated in the same tunnel, such as packages, sacks or boxes. The tunnel can handle very small items from 300 grams as well as larger items up to 35 kilos. Even soft bags that are otherwise difficult to handle can be treated optimally in this tunnel. The waterfall model can supply materials, for example for automatic storage systems, and comes with a standard belt speed of up to 0.1 m/s.

High Speed Unit

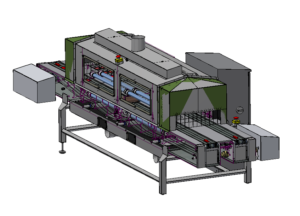

When things have to move quickly, you need the high-speed model. Here, you get a speed of up to 1 m/s as well as great variation in the different types of items it can handle. The tunnel is designed to be placed between existing belt sections as an independent disinfection unit. It has band sections with several transitions in quartz glass, where UVC lamps are mounted and ensure 360° disinfection of all surfaces.

The High Speed Unit can be used in the distribution industry, where it can secure high-capacity incoming and outgoing products, or as additional security in the service industry, e.g. in hotels or airports.

This tunnel is equipped with self-cleaning of the double entrance and exit sections, which shields direct light and ensures a safe working environment around the unit.

Wire Mesh Unit

Wire Mesh Unit

Our wire mesh tunnel is designed with one or more bands in wire mesh, which can process almost all types of light products. A unique construction with a loop on the belt ensures that the product changes position in the process so that the UVC lamps have access to all surfaces. We also supply this unit for use with, for example, pick and place robots that can be combined with several wire bands in both directions.

The Wire Mesh Unit is suitable for many types of products, such as packaging, components and raw materials, which need to be used for a process and have to be disinfected before packaging or production. The tunnel can handle many different types of goods at up to moderate speed.